Electrical design for panel building

The design of enclosures and switchgears is often challenged by tight deadlines, price pressures and a high level of fixed costs for electrical equipment, packaging and wages. This remains true for all areas, from electrical engineering to industrial automation and power distribution to network technology. Moreover customers can be demanding, requiring customised solutions, short production times, timely introduction, high quality switchgears and accurate documentation – all at a low cost. Therefore, small batches and solitary orders pose a difficult challenge when striving for efficient production.

Consequently, it is necessary to uniformly improve process quality by restructuring data workflows in product development. Continuity and compatibility of data and systems are both the starting

point and the objective – starting with engineering, order preparation,

material logistics, production and assembly - continuing throughout

setup and commissioning at the customer site.

Continuity and compatibility of data and systems are both the starting

point and the objective – starting with engineering, order preparation,

material logistics, production and assembly - continuing throughout

setup and commissioning at the customer site.

Your partner: Shellau Contracts & EPLAN Software

Our engineering tools let you provide data across all disciplines by automatically adapting to different trade-specific requirements. Our systems and consultants can offer their experience in process engineering requirements including enclosure and switchgear product development.

EPLAN engineering solutions are based on a thorough analysis of your existing IT and engineering system environment, and focus on providing software solutions that consistently support and optimise the product development process. This applies to all engineering practices including electrical engineering design, mechanical mounting layouts, manual or automated production, assembly and commissioning at the customer site.

Our goals – your benefits:

- Data consistency throughout engineering processes and systems

- Centralised data management

- Elimination of redundant data entry

- Eradication of inconsistencies

- Interdisciplinary cooperation and consistacy within the development process

- Reduced time to market

- Sustainable cost reduction

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur pharetra dapibus pharetra. Donec interdum eros eu turpis pharetra et hendrerit est ornare. Etiam eu nulla sapien. Nullam ultricies posuere nunc, eget mollis nulla malesuada quis.

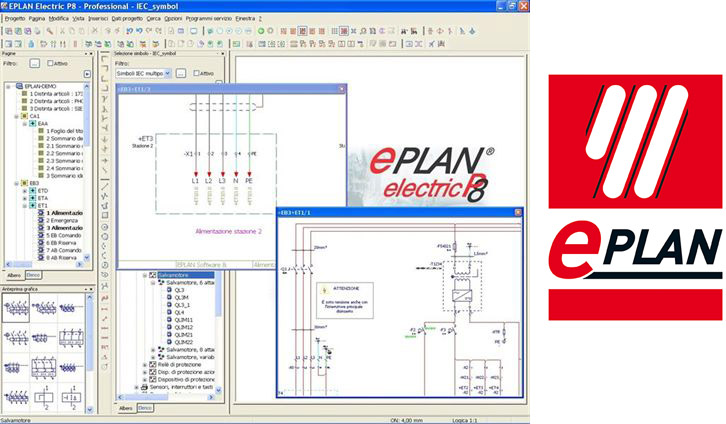

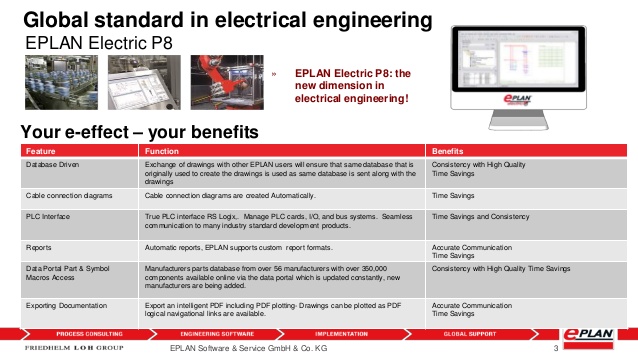

Electrical Engineering Design Software

EPLAN Electric P8 is an electrical engineering design software program that offers unlimited possibilities for project planning, documentation, and management of automation projects. The automatic production of detailed reports based on wiring diagrams is an integral part of a comprehensive documentation system and provides subsequent phases of the project, such as production, assembly, commissioning and service with the data required. Engineering data from other project areas such as fluid and pneumatic engineering can be exchanged via interfaces within our CAE software. This therefore guarantees consistency and integration throughout the entire product development process.

Additional benefits

- Store unlimited, simple, complex or scalable schematics with ease

- Options technology

- Language translation

- Instant multi-user access

- Intelligent parts selection and management

- Conversion into electrical engineering standards including IEC, GHOST and NFPA

- Automatic conversion into PDF, DWG, XML files

- Data exchange with PLC

- Pre-schematic engineering

- Bus topology representation

Benefits of EPLAN over traditional CAD packages

EPLAN develop

solutions for greater efficiency, putting integration and automation at

everything it does by providing end-users with all the core functions

required of an electrical design package, and easily-integrated

additional tools that can be adapted for industry-specific processes;

from fluid and pneumatic engineering to enclosure design.

As a result, EPLAN offers many advantages over traditional CAD packages. The main benefits include:

- The ability to automatically connect, mend or break lines

- Instantaneous device tagging and wire numbering

- Provision of point to point wire lists

- Automatic creation of reports and BOM's

- Provisions that go far beyond providing the software itself, for example, by offering our Data Portal which delivers online device data on over 500,000 components from leading manufacturers such as ABB, B&R, Eaton, Mitsubishi Electric, Omron, Phoenix Contact and Schneider Electric.

You determine the method of operation

EPLAN provides users with advantages throughout all project phases; from generating initial graphical layouts or plant overviews to creating schematics and other project information, independently of graphics. This is achieved as our electrical engineering software supports these different phases with equal priority. Users can automatically select the operation most suited to their requirements; providing continuous consistency in the project data, regardless of your method of design.

Project documentation – quantity and quality

With comprehensive and individually configurable check runs, you determine how strictly EPLAN monitors the quality level of your documentation. In this way, the downstream stages of the process are provided with all of the required information – supporting continuous product creation from manufacturing, installation, commissioning, servicing and maintenance.

Internationally standardised and continuously localised

EPLAN Electric P8 supports global standards such as IEC, NFPA, the Russian GOST standard and the Chinese GB standard with appropriate master data and sample projects. The optional standard conversion ensures that you remain competitive as globalisation increases. Thanks to continuous Unicode capability, EPLAN Electric P8 provides schematics in any language on the basis of your individual translation databases – from Chinese circuit diagrams to Russian part lists, everything is translated online or as soon as the plant is complete.

Added value at a glance

The combination of standard functions and optional extensions in EPLAN Electric P8 allows you to optimise your entire planning process and increase the quality of your automation documentation in the long term.

- Graphical and device-oriented planning

- Automatic and individual DT allocation and connection numbering

- Automatic creation of cross references between

- Interruption points, contacts, symbols and components, PLC’s

- Single line, multi-line display and mounting layout

- Different subsystems (E-technology, fluid power and I&C)

- Auto connecting and Smart connecting

- Macro variants, value sets and project-wide option technology

- Automated processing using scripts

- Integrated IEC, NFPA, GOST and GB symbol library

- Quick and easy navigation with “go to” and search function

- Mass editing of project data in Excel

- Undo and redo function

- Checking procedures for signalling logical planning errors

- Quick information and context-sensitive help

- Adaptable layer management for selective display of project data

- Navigators for rapid project data locating and direct processing

- Automatic addressing of PLC components (I/Os)

- Integrated part management with configuration of the part structure and SQL access

- Unicode capability for project creation and translation in any language

- Project, version and rights management

The functions and options always relate to the maximum configuration of the product.